When propane prices spiked at over $5 a gallon this winter, Murphy Biglow didn't freak out despite having almost 100,000 chickens to keep warm.

Biglow simply threw another log on the fire. Or more accurately, he threw another bundle of slabs into the wood stove.

Biglow, and his wife Joan, began raising chickens on his farm east of Goodman in 1991, mostly so he would have the litter to fertilize his pasture instead of having to buy commercial fertilizer.

"When I started growing chickens in 1991, propane was 42 cents a gallon," Biglow said. "But propane started getting higher and higher so I knew I needed to do something."

Biglow said he went to a couple of universities to research about some type of low-cost heating, but hadn't come upon the solution when one day in 2007 he was driving through Diamond.

"I saw smoke coming from behind a chicken house," Biglow said. "I stopped to see what it was."

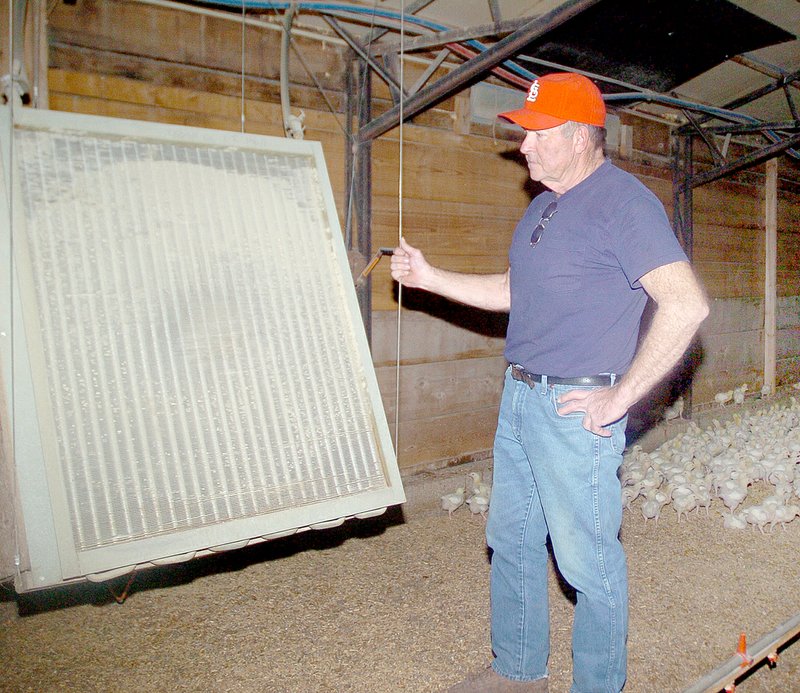

Biglow found that it was what was called a "hay burner," a furnace that used big bales of hay as its heat source. The furnace heats water that is circulated by a system of lines throughout the chicken house where heat exchangers and fans take heat from the water to heat the air. There are five heat exchangers in each house.

It so happened that Biglow knew the poultry farmer who was using the hay burner. It was Bruce Youngblood, who invented and built the system.

"I talked him into building one for me," Biglow said. "Instead of burning hay, I use slabs from the sawmill. It worked so good for me, both of my sons-in-law had one made for them. It was just what I wanted without having to go through the learning experience."

Biglow said the last year he relied 100 percent on propane he used 19,000 gallons. He said the first year he went to wood, he used 3,500 gallons of propane. The slabs cost him $15 a bundle delivered and he burns 3-4 bundles on the coldest of days. One furnace supplies the heat for each of Biglow's four poultry houses.

"This February I used 950 gallons of propane for one whole flock (35 days)," Biglow said. "And they say this was the coldest February we have had since 1979. I can go a whole year and the gas company comes twice. Without wood heat, they would come and fill me up every week."

Biglow said on the day it was 12 below, he used four bundles of slabs. He said the propane heaters only ran 23 percent of the time despite it being 12 below and the chicken house was at 90 degrees. That percent drops down to below 10 percent when the temperature gets into the 20s.

"Without wood, the propane heaters would have never shut off," Biglow said.

Youngblood said he saw the demand for his wood heating system and started a company B and D Heating to supply the system to poultry farmers, both locally and nationally. The brand name of the patented furnace is Agriflame.

"I have a manufacturer in Topeka, Kan. building the stoves," Youngblood said. "I set them, sell the radiators, pumps and additives so the lines don't rust. I don't install the lines, but tell everyone how to do it. They can install them themselves or hire it done. If they hire everything done, the total cost is about $85,000."

Youngblood said there is a grant that pays for 25 percent of the cost.

Youngblood's stoves come in three sizes: 7 by 12 feet, 7 by 10 and 6 by 7. You can use any combustible you want in the stove.

"A lot of guys are still burning hay," Youngblood said. "You can use corn stalks, hay, slabs, whatever you want. It puts out about 3 to 3.5 million B.T.U.s. We are making heat for about the equivalent of 25 cents a gallon."

In addition to the cost savings, since the heat source is outside the chicken house, the moisture that comes from burning propane isn't created.

"This keeps the houses a lot drier," Biglow said. "You can see where the chickens scratch in the dust."

Youngblood said he put in a system for one grower who told him the main reason he was switching to wood was so he could get the moisture out of his houses.

Biglow said to be truthful there was a down-side to using wood.

"I used to get about $1,200 in refunds from the propane company each year and I would take Joan to Branson a couple of times," Biglow said. "Now I get about $75 and we have been going to Sonic ever since."

Community on 04/10/2014